The Magnapower Frag Drum is the primary ferrous metal separator in steel scrap processing plants. It separates the majority of steel prior to any other separation process. It tends to process high throughputs of heavy sharp ferrous metal and so needs to be of very heavy-duty construction, reliable and efficient.

We have a strong commitment to providing separators which are the leading performers in the separation industry. Our equipment is designed and built to be reliable and durable even in the toughest environments such as this.

- Higher levels of cleaner ferrous metals – alternating poles to release non-magnetics and non-ferrous metals

- Heavy duty parts and construction to reduce wear and maintenance

- Magnetic force focused into product only where it is needed

- Deep field permanent magnets available where electro magnets used to be the only option

- Excellent back up and service

Our commitment is to provide separators which are the leading performers in the industry.

Operation

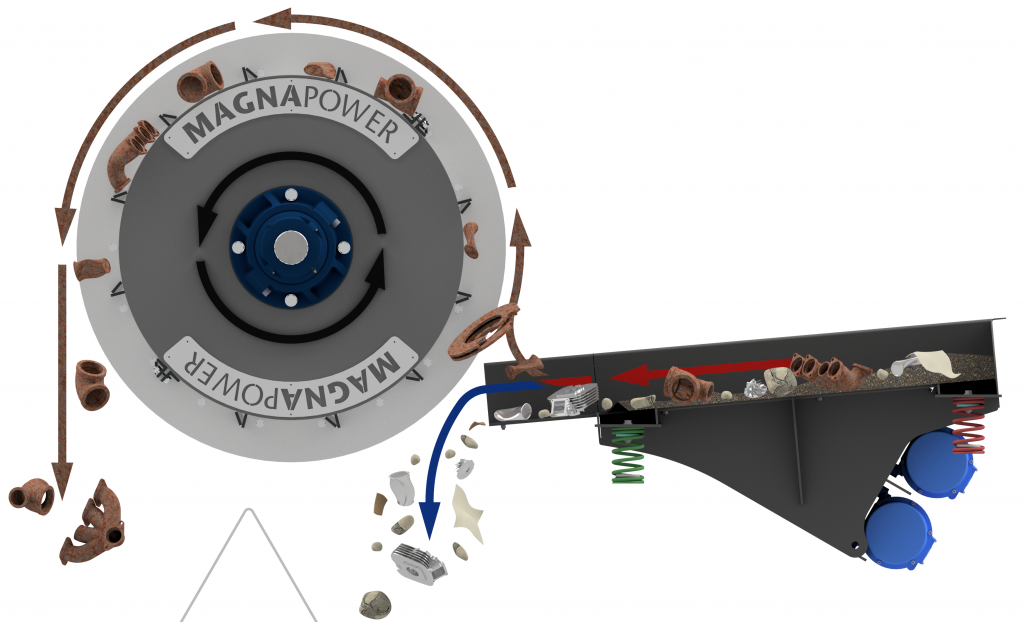

Shredded material is presented to the underside of the drum magnet by non-magnetic vibratory feeder or conveyor.

Ferrous metal is attracted to the magnet surface allowing non-magnetics and non-ferrous metals to drop through the gap.

The ferrous metal is carried upwards around the drum. The magnetic field alternates from north to south and this causes the ferrous metal to turn and flip. This allows more non-ferrous metals and non-metals to be released and so a clean ferrous metal product is produced.

- Alternating magnetic poles to release trapped non-ferrous items from the steel frag

- Deep field magnet systems to allow maximum gaps for non-ferrous items to drop away

- Manganese steel (work and wear hardening) drum skin, wear cover & flights

- Stainless steel end flanges

- Cooper type (split) bearings

- Fully guarded chain gear – oil sump or open type

- SEW motor gearbox