Eddy Current Separators from Magnapower are the world leading non-ferrous metal separator.

It is suitable for a wide range of applications from the recovery of small non-ferrous metals to larger shredded scrap metal processes. We have a strong commitment to support our customers and provide metal separators which are the leading performers in the industry. Our equipment is designed and built to be reliable and durable in the toughest environments.

Our fast response time at all stages from enquiry to service & support ensures you have our expertise whenever you need it.

The Magnapower Eddy Current Separator provides:

- Higher levels of cleaner non-ferrous metals

- Maximum performance and reliability with the eccentric rotor

- Long life reliability of high performance & high frequency rotor

- Belt widths: 300mm to 2000mm

- Higher throughput with variable high speed belt

- Simple belt changing and maintenance

- Our application and selection expertise is at your service

- Excellent back up and service

- 12 months standard guarantee – extended guarantees available

- Full service contracts available

We also have a full testing facility to confirm your performance prior to purchase.

Operation

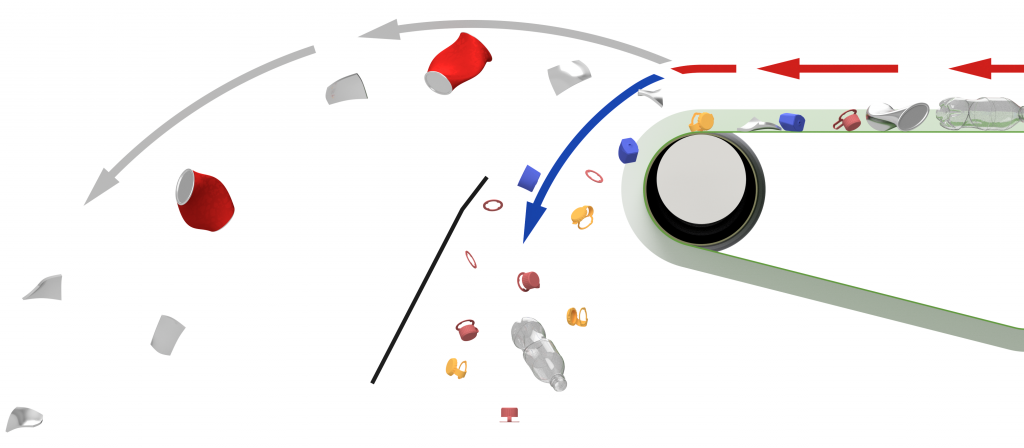

A high frequency high intensity magnetic rotor inside the head drum of the ECS conveyor induces a magnetic field into non-ferrous metals on the belt surface. These magnetically induced metals react with the magnetic field of the rotor which causes them to be propelled forward further than the other material on the belt. The performance is determined by a combination of flux density and frequency – to find out why the Magnapower ECS is an industry leader then please ask.

Eccentric Rotor

A key advantage of the eccentric rotor is that ferrous metal is significantly less damaging than it would be to a concentric rotor. Ferrous metal heats up very rapidly on an ECS and needs to discharge quickly before causing damage. The eccentric rotor allows ferrous to discharge easily from the rotor. On a concentric rotor it discharges less easily and causes significant wear and damage. The Magnapower eccentric rotor is also designed to give a higher separation force to provide greater performance and reliability.