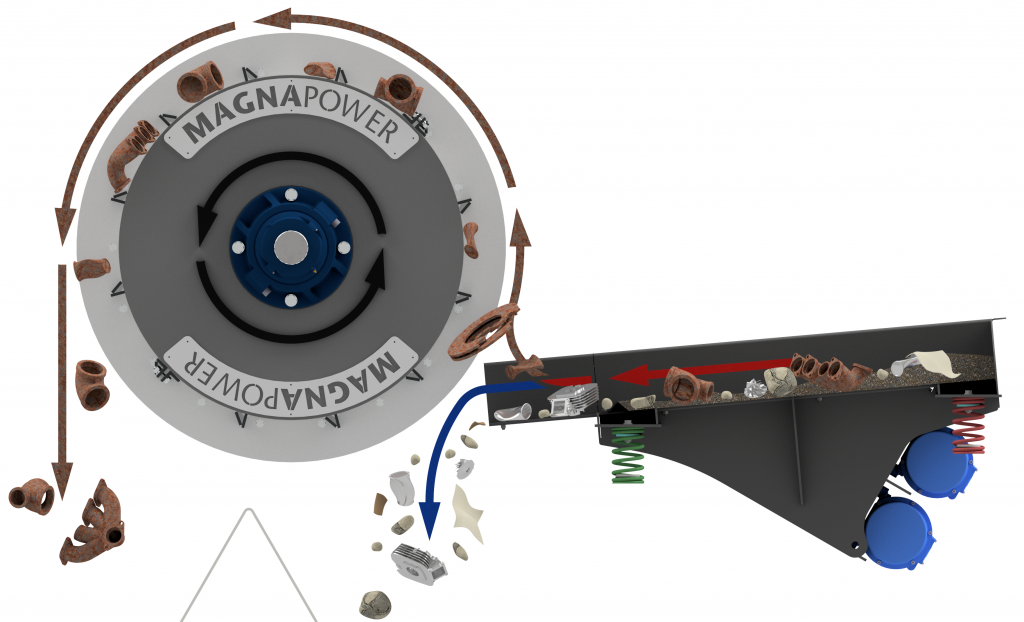

The Magnapower PowerFrag provides the next generation of Frag Drums.

It improves separation efficiency and requires no electrical power to the magnet system.

It combines the mechanical features and strengths of the standard electro frag drum but with a stronger magnetic intensity and more alternating poles to release more non-ferrous metals and provide a cleaner ferrous fraction.

Operation

Shredded material is presented to the underside of the drum magnet by non-magnetic vibratory feeder or conveyor.

Ferrous metal is attracted to the magnet surface allowing non-magnetics and non-ferrous metals to drop through the gap.

The ferrous metal is carried upwards around the drum. The magnetic field alternates from north to south and this causes the ferrous metal to turn and flip. This allows more non-ferrous metals and non-metals to be released and so a clean ferrous metal product is produced.

PowerFrag

- Higher levels of ferrous extraction

- Cleaner metals – more alternating poles

- Constant intensity during the day – compared to most electro drums which are up to 50% weaker at the end of the day compared to the start due to heating of the magnet coils

- Wider magnetic coverage across the drum face

- Reduced running costs – no electrical supply to the magnet system

- No maintenance of the electro magnet

- No transformer or dc cable required