7th December 2021

In early 2021, St Helena Government joined an extensive recycling programme, actively recycling glass, plastics & aluminium drink cans to benefit the environment.

Volumes of waste needing to be landfilled on the island are increasing & the available landfill space is rapidly reducing, giving St Helena Government the opportunity to replace & restore the Horse Plant Landfill site & use it as a Metals Recycling Facility (MRF) *¹

The new MRF will be fitted out with compactors & balers, including a Magnapower Can Sorter to aid sorting of aluminium drink cans, cardboard & plastic.

Olympic bins have been located across the island and these are then collected & delivered to the Recycling Facility at Horse Point Landfill site for recycling. *²

Magnapower are proud to support St Helena Government within this scheme by providing one of our very own Magnetic Can Sorters.

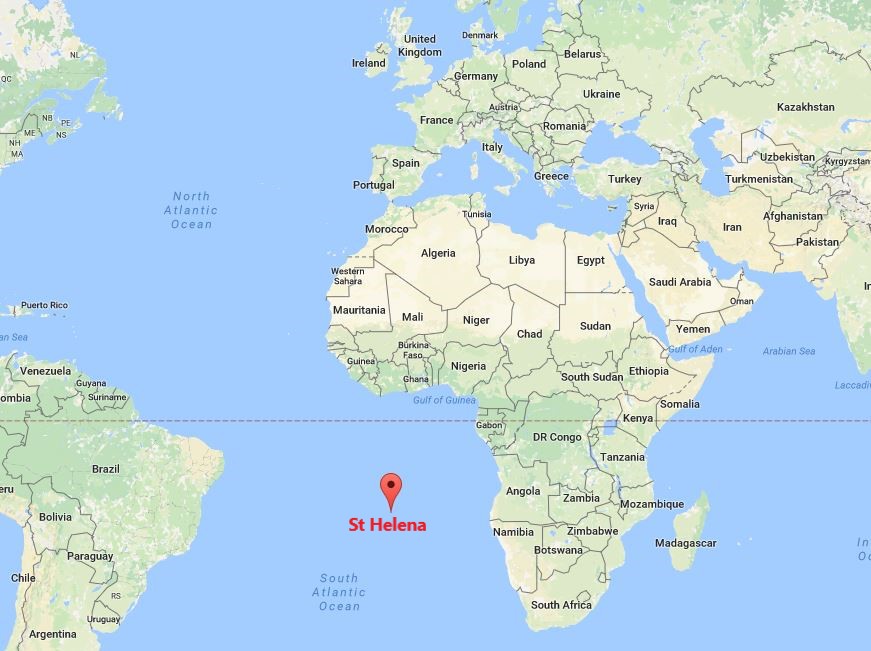

St Helena, located 2500 miles from east of Brazil, has a population of approx. 4500 & is 47 sq. miles in size – in comparison, that’s about half the size of Scotland’s capital, Edinburgh!

Standing at 2m tall with a hopper capacity of 0.25m³ & throughput of 1 tonne per hour, the Magnapower MCS 30 Can Sorter is perfect for St Helena’s needs.

The Magnapower Can Sorter has been designed & developed to provide the most compact and efficient method of sorting aluminium & steel cans.

Every year in the UK, around 9.6 billion aluminium drink cans are producing in the UK, 75% of which can be recycled!

How does it work?

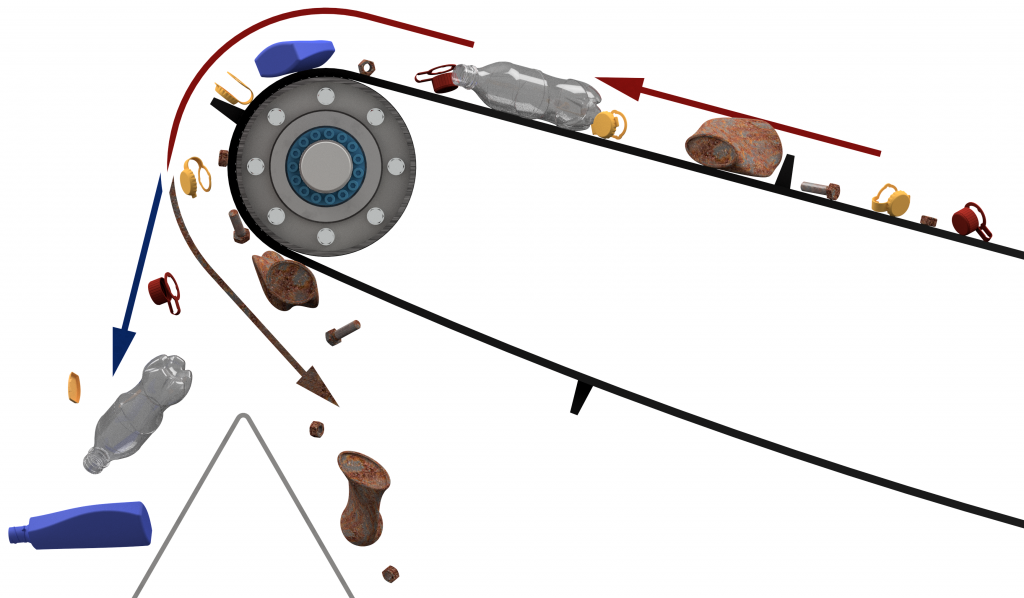

Mixed cans are poured into the hopper at the top of the can sorter. The constantly moving belt carries the cans up to the Magnetic Head Pulley (required for ferrous sorting) of the conveyor.

Aluminium cans & other materials such as paper or plastic, drop off the end of the conveyor, whilst ferrous cans are held onto the surface of the belt.

These cans are then carried back under the head pulley where they are discharged into the “ferrous cans” chute.

Magnetic Head Pulley – Schematic Magnet Head Pulley in Aluminium foundry

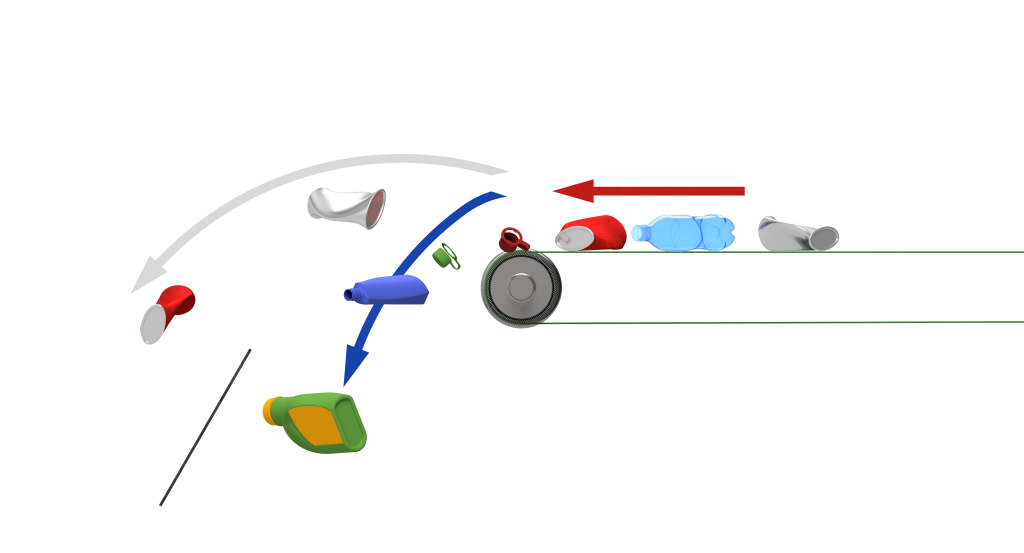

For the further removal of other materials such as glass, paper & plastics from the aluminium, an Eddy Current Can Separator can be used.

Our cost-effective Eddy Current Separator sorts the non-metallic from the aluminium using a magnetic field which is induced into the aluminium on the belt surface.

These magnetically induced cans react with the magnetic field of the rotor causing them to be propelled forward, further than the other material on the belt which will simply drop off.

Eddy Current Can Separator Eddy Current Can Separator – Schematic

Due to St Helena’s remote location, limited economy & an aid dependant nation (from the FCDO), this often means development opportunities are limited.

This being so, it is important for them to maximise the benefits of the funding received to develop commercially the recycling of wastes on the island. Not for just today, but for future generations & to contribute towards climate change. *³

You can read more about how Magnapower metal separators save energy & cost in the fight against climate change in one of our latest posts via our new website CLICK HERE