EQUIPMENT

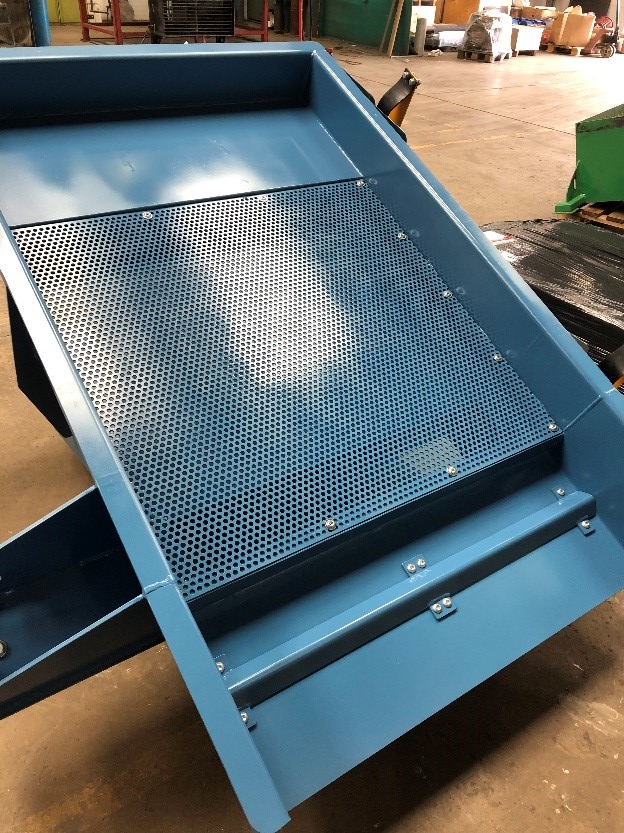

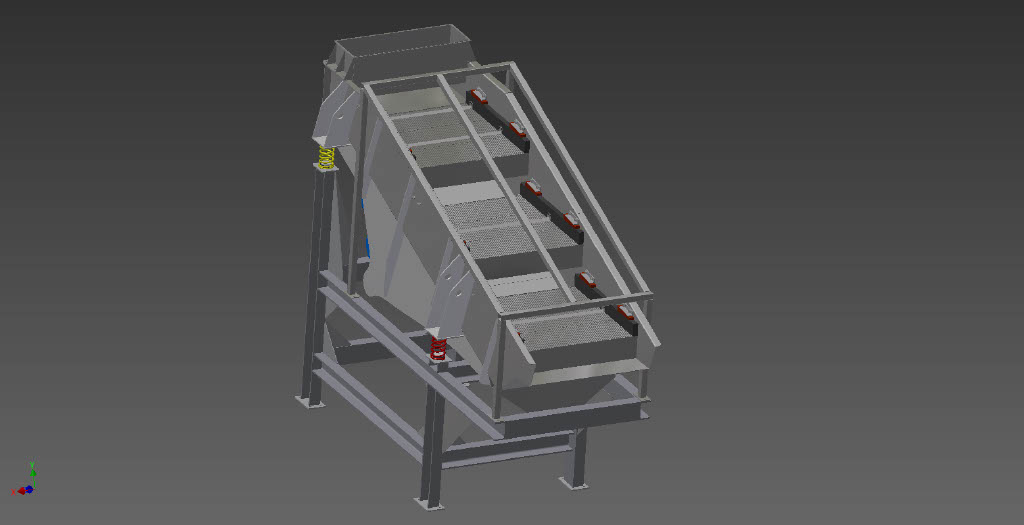

Custom-built belt conveyors for metal separation

We design and manufacture our own belt conveyors when required as auxiliary equipment to our range of metal separators. These will include the necessary non-magnetic sections required for the metal separation equipment. The conveyors will tend to be designed for each application and use high quality parts and are of robust and heavy-duty construction. Drive motor gearboxes will either be shaft mounted or through a coupling. In some instances, we will use motorised drive pulleys.

Please contact us for details of any conveyors which are allied to our separation equipment e.g. overband magnets and magnetic head pulleys.