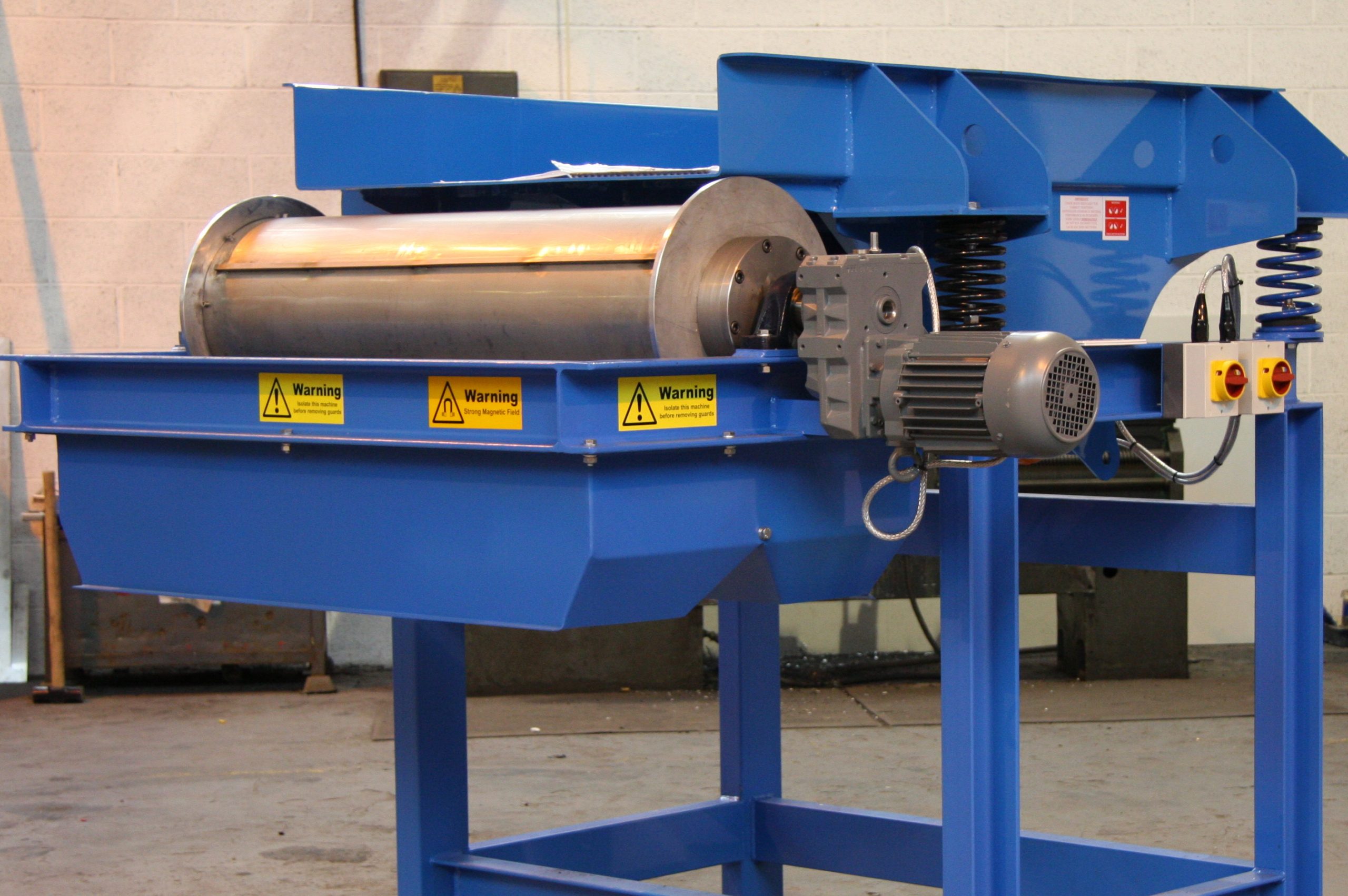

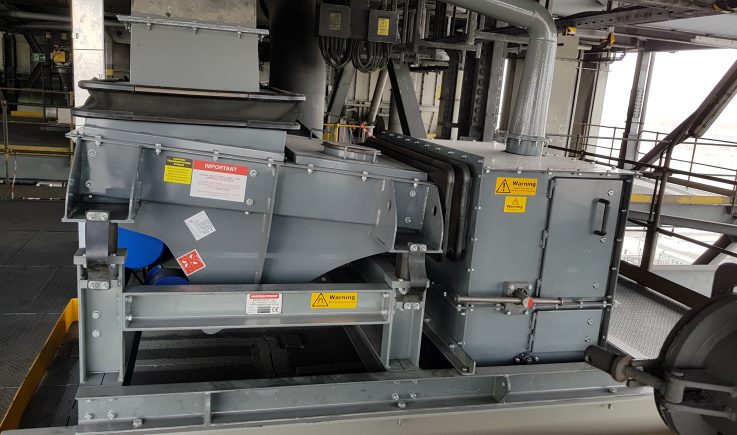

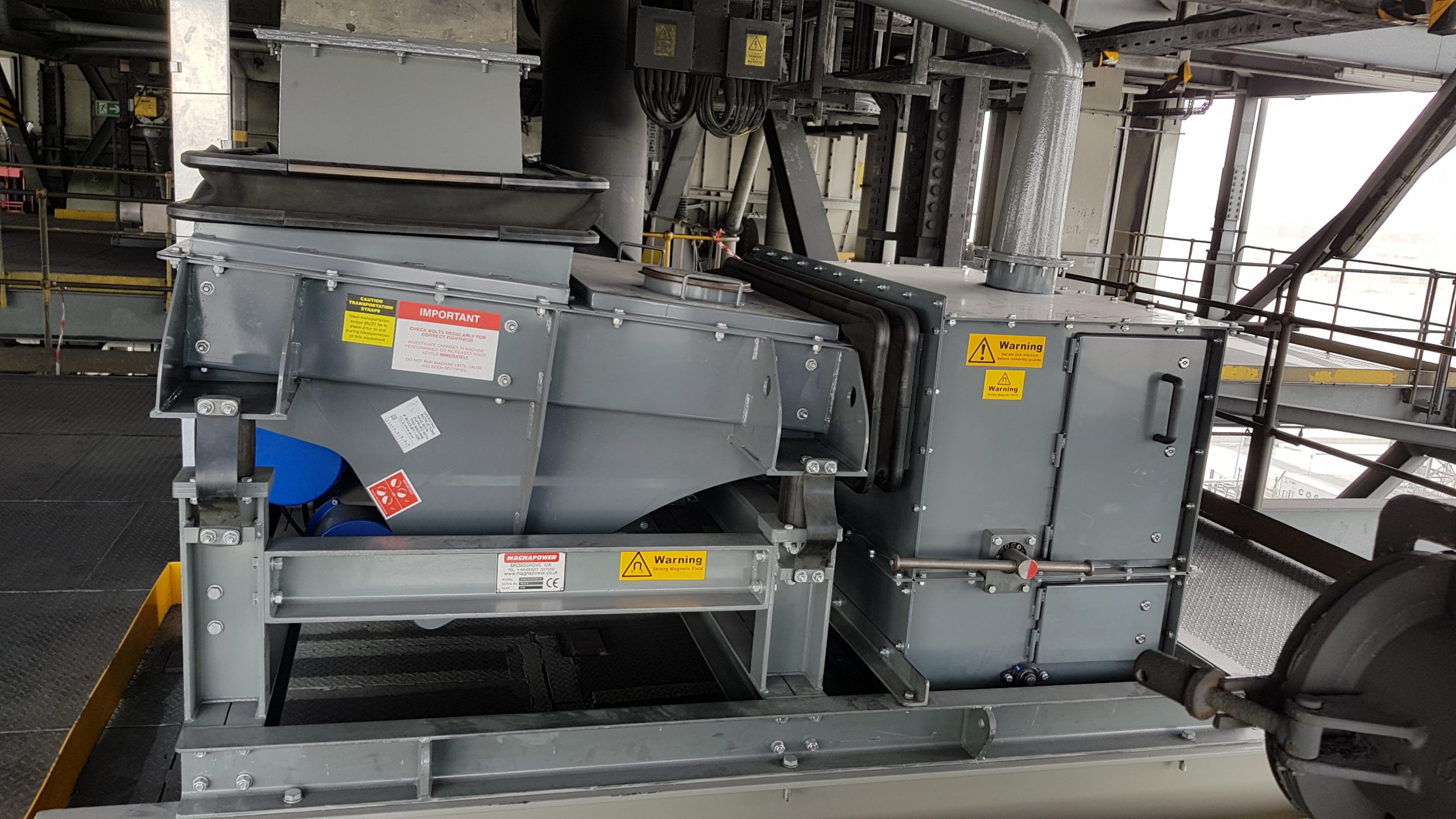

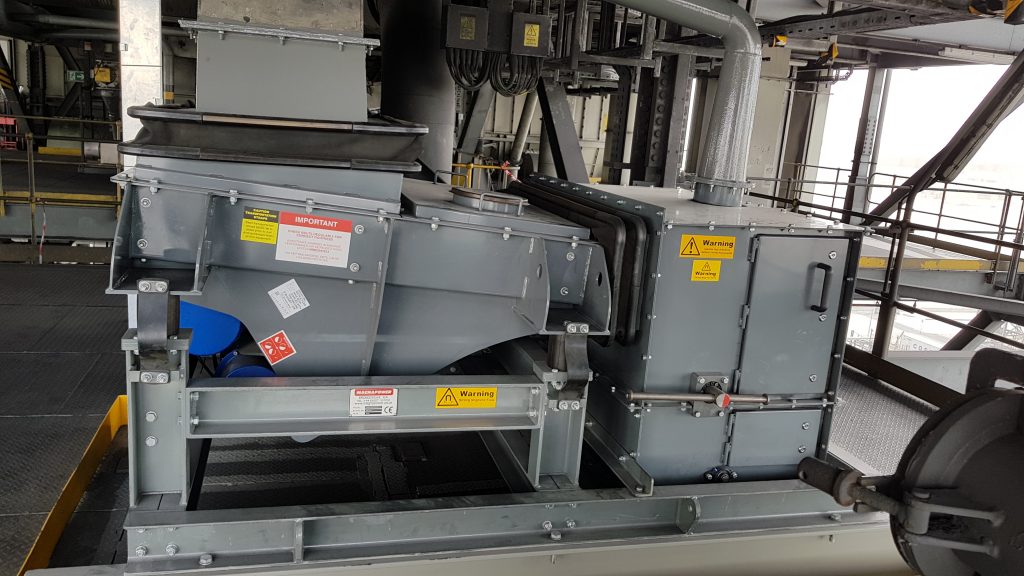

The Magnapower range of Drum Magnet Separators are designed and manufactured to provide the highest possible ferrous metal recovery rates. Drum Magnets have heavy duty parts and construction and are built to an industry setting standard. They are renowned for high performance and reliability.

We have a strong commitment to providing separators which are the leading performers in the separation industry. Our equipment is also designed and built to be reliable and durable even in the toughest environments.

Our separators provide:

- Higher levels of cleaner ferrous metals

- Heavy duty parts and construction to reduce any maintenance requirements

- Magnetic force focused into product only where it is needed

- Deep field permanent magnets for applications where electro magnets used to be required (significant cost savings)

- Our new range of high working gap In-Line separators improve ferrous purity and reduce maintenance

- Magnet selection expertise at your service

- Our application and selection expertise is at your service

- Excellent back up and service

- 12 months standard guarantee – extended guarantees available

- Full service contracts available

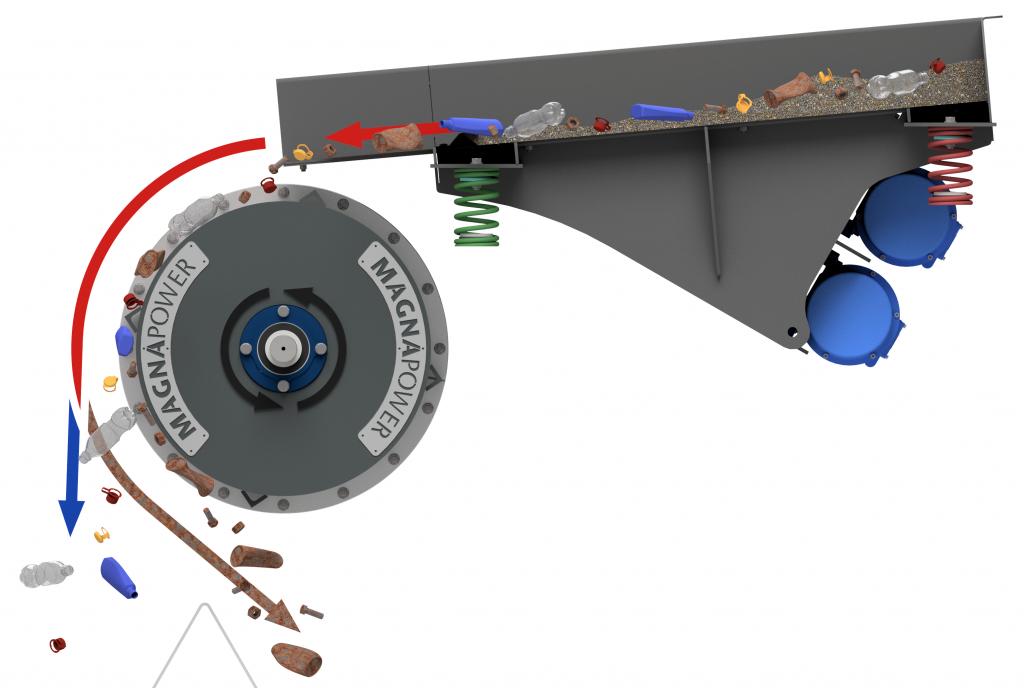

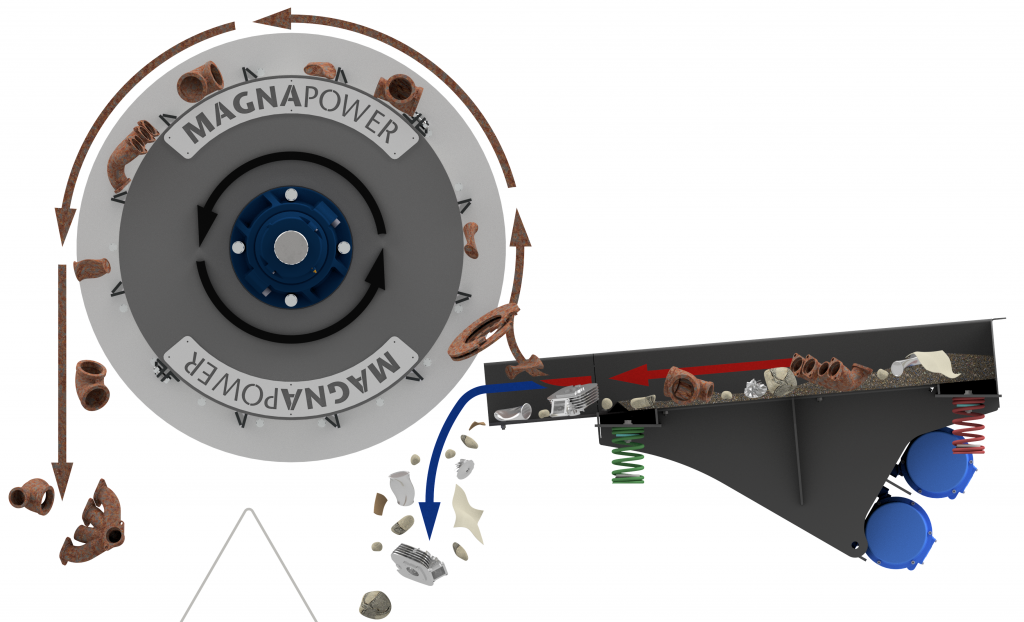

Our range of Drum Magnets continuously remove ferrous metals from non-magnetic material that is fed to the surface of the magnetic drum. We are able to specify and design a drum magnet suit your separation requirement, feed width, product size and throughput.

Magnet System

Magnapower drum magnet systems can be from one of the following:

Permanent Deep Field Ferrite – standard for most applications – either single pole or double pole

Permanent Rare Earth – ideal for lighter weight, heavy duty high performance units

Permanent Drum Magnet

- High Intensity Permanent Magnet System (guaranteed non-deteriorating) that is

suitable for most applications - Ferrite and Rare Earth magnet systems offered

- Wear resistant non-magnetic drum skin

- Can be supplied as a drum only or optional extras include a drum frame, chutes, guards

and a geared motor - Drum Magnets are also available with full enclosures

Operation

Feed position. We will assist you in determining which is the best type of drum magnet and feed position for your product. Possible options are:

Top fed:

Material is presented to the top surface of the drum magnet. All material is carried a short distance around the rotating surface of the drum. Non-magnetic material will drop away by gravity but ferrous metal is held by the magnetic field to the rotating surface of the drum and carried further round to a point outside the magnetic field where it then drops away.

Curtain fed:

Similar to top fed except material is presented in a falling stream (or curtain) passed the surface of the drum magnet. Non-magnetic material continues to drop away by gravity but ferrous metal is held by the magnetic field to the rotating surface of the drum and carried further round to a point outside the magnetic field where it then drops away.

Bottom fed:

Material is presented to the under side of the drum magnet. Ferrous metal is attracted to the rotating surface of the drum which carries it over the drum to discharge. Non metals drop from the feeder clear of the magnet.

We also manufacture a comprehensive range of Frag drums.